Henan Qianna Trading Co., Ltd.

Tel: +86-0371-65015556

Mob: +86-15544129888

E-mail: info@qn-abrasive.com

Abrasive discs cut or grind due to the abrasive grains that compose them. This is due to the fact that the binder (natural or synthetic), binds the abrasive grains with different strength to each other so that depending on the purpose of the disc, it has more or less hardness, speed or depth of cut; or roughing capacity.

Therefore, depending on the application you are looking for, there are different types.

Do you know the difference between abrasive cutting discs, grinding discs and flap discs?

The main difference between grinding, flap and cutting discs is that the first two are used to smooth surfaces, remove weld seams and grind edges; and the third to cut.

The grinding discs have a larger and thicker abrasive grain; and the depressed center to favor its resistant to the torsion, has less vibrations and a homogeneous wear.

While flap discs, are formed by several abrasive fabrics depending on the application, and their center is usually depressed when it is going to be used for roughing, although they also exist with a flat center.

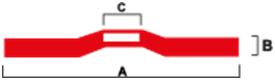

However, the cutting discs have a smaller grain size, and a less concave or even flat center.

Flat center T41 Depressed center T27 y T42

Finally, it is important to mention that, it is necessary that the grinding and flap discs must be placed at an angle of 20-30 ° with respect to the material, and the cutting discs at 90 °. In this way the cut will be safer and with a perfect finish.

20-30° angle 90° angle