Henan Qianna Trading Co., Ltd.

Tel: +86-0371-65015556

Mob: +86-15544129888

E-mail: info@qn-abrasive.com

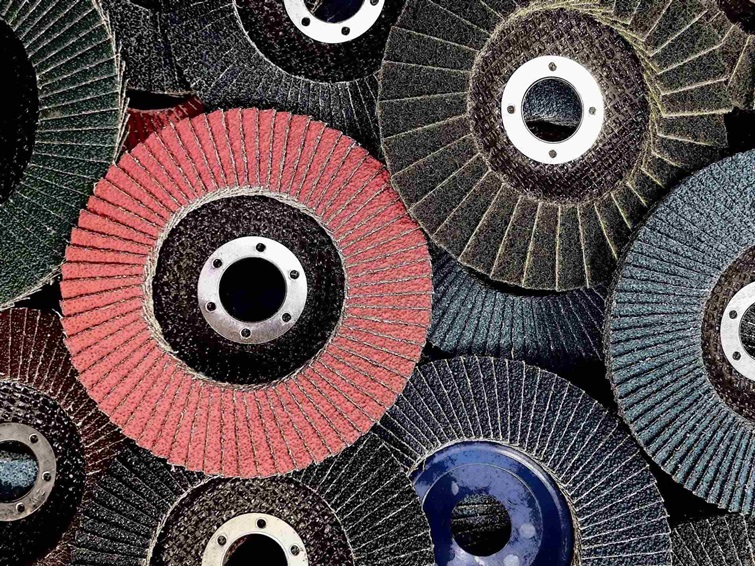

Flap discs can be classified into three main categories based on the type of abrasive used: ceramic alumina, zirconia alumina, and alumina.

Ceramic Alumina: This type contains numerous crystals and is known for its excellent self-sharpening properties, clean cutting edges, good heat dissipation, and long service life. Due to these features, ceramic alumina flap discs are primarily used for grinding hard metals such as stainless steel and aluminum.

Zirconia Alumina: Zirconia alumina is a polycrystalline material with a fast cutting speed, self-sharpening ability, and strong resistance to high pressure and temperature. As a result, zirconia alumina flap discs offer strong cutting performance and a long service life, making them ideal for heavy-duty applications.

Alumina: Composed of monocrystalline crystals, alumina abrasives begin to lose their cutting ability early in the grinding process, and their abrasive particles are less prone to breaking. Alumina flap discs are best suited for processing common metals, offering good value for general-purpose grinding tasks.