Henan Qianna Trading Co., Ltd.

Tel: +86-0371-65015556

Mob: +86-15544129888

E-mail: info@qn-abrasive.com

1. Abrasives

Abrasives are the main raw materials for manufacturing cutting discs, and they are responsible for grinding. Therefore, abrasives must be sharp and have high hardness, good heat resistance and certain toughness.

2. Particle size

Particle size refers to the size of abrasive particles. Particle size is divided into two categories: abrasive particles and micro powder. Abrasives with a particle size greater than 40μm are called abrasive particles.

3. Hardness

Hardness refers to the ease with which abrasive particles on the surface of the cutting disc fall off under the action of grinding force. The softer the hardness of the cutting disc, the easier it is for the abrasive particles to fall off; the harder the hardness of the cutting disc, the more difficult it is for the abrasive particles to fall off.

4. Organization

Organization refers to the proportional relationship between the volumes of the abrasive particles, binders, and pores that make up the cutting disc. The smaller the tissue number, the greater the proportion of abrasive grains and the tighter the grinding wheel; conversely, the larger the tissue number, the smaller the proportion of abrasive grains and the looser the cutting disc.

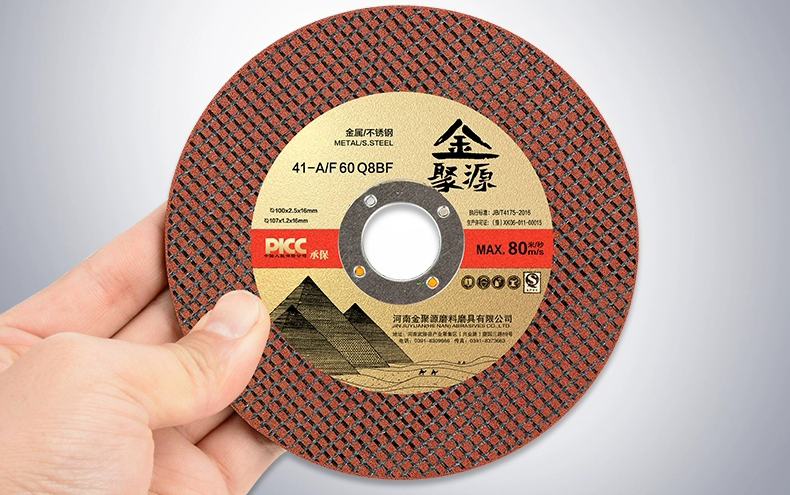

5. Shape and size

Cutting discs can be made into various shapes and sizes. The outer diameter of the cutting disc should be selected as large as possible to increase the circumferential speed of the cutting disc, which is beneficial to improving the grinding productivity and surface roughness.