Henan Qianna Trading Co., Ltd.

Tel: +86-0371-65015556

Mob: +86-15544129888

E-mail: info@qn-abrasive.com

Cutting disc introduction

Diamond cutting is a cutting tool widely used in the processing of hard and brittle materials such as stone, concrete, prefabricated panels, new and old roads, ceramics, etc.

Manufacturing process

1.Sintered diamond cutting blade: divided into cold pressed sintering and hot pressed sintering.

2.Welding diamond cutting blades: There are two types: high-frequency welding and laser welding. High-frequency welding welds the cutter head and the substrate together through a high-temperature melting medium. And laser welding melts the contact edge of the cutter head and the substrate through a high-temperature laser beam to form a metallurgical bond.

3.Electroplated diamond cutting blade: The blade powder is attached to the substrate by electroplating.

Processing range

1. Suitable for cutting terrazzo marble.

2. Cutting of cement pavement, hard refractory materials and non-metallic materials.

3. Grooving of roads, bridges, and rivers with grooving blades.

4. Engraving of pavement and bridge decks with road engraving blades.

5. Widely used in municipal construction, road reconstruction, airport runway construction, concrete pavement and other construction sites, especially suitable for professional cutting operations such as asphalt and concrete pavement cutting.

Cutting disc classification

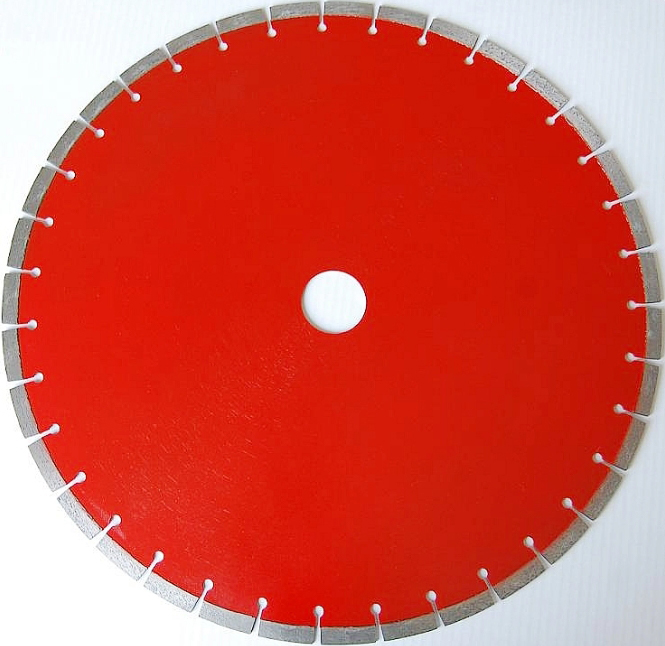

1. Continuous edge saw blade: Continuous sawtooth diamond cutting blade, generally made by sintering method, often using bronze binder as the basic body material, water must be added during cutting to ensure the cutting effect, and there are types that use laser to cut the gap of the blade.

2. Blade type cutting blade: The saw teeth are disconnected, the cutting speed is fast, and it is suitable for both dry and wet cutting methods.

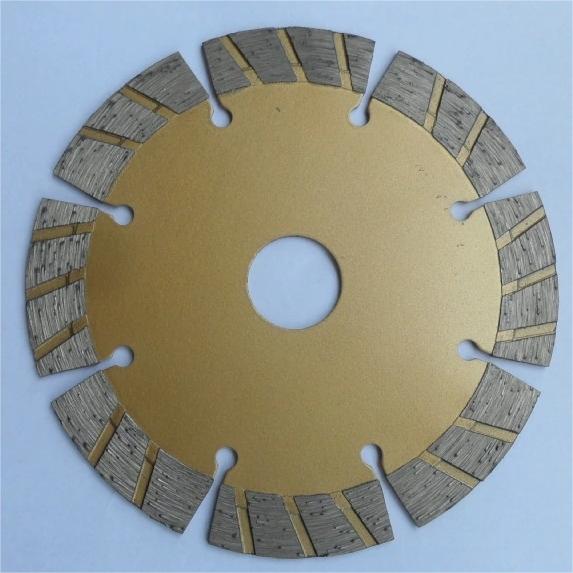

3. Turbine type cutting blade: Combining the advantages of the previous 1 and 2, the saw teeth are continuously turbine-shaped and uniformly convex and concave, which increases the cutting speed and increases the service life.

Different materials use different types of diamond saw blades, and different powder formulas are suitable for the characteristics of different materials, which directly affects the quality, effect, qualified rate and even cost and benefit of material products.

Factors affecting the efficiency and life of diamond circular saw blades include sawing process parameters and diamond particle size, concentration, binder hardness, etc. The cutting energy parameters include saw blade linear speed, sawing concentration and feed speed.